The new way of erecting houses is no longer brick by brick, but layer by layer of 3D printed materials!

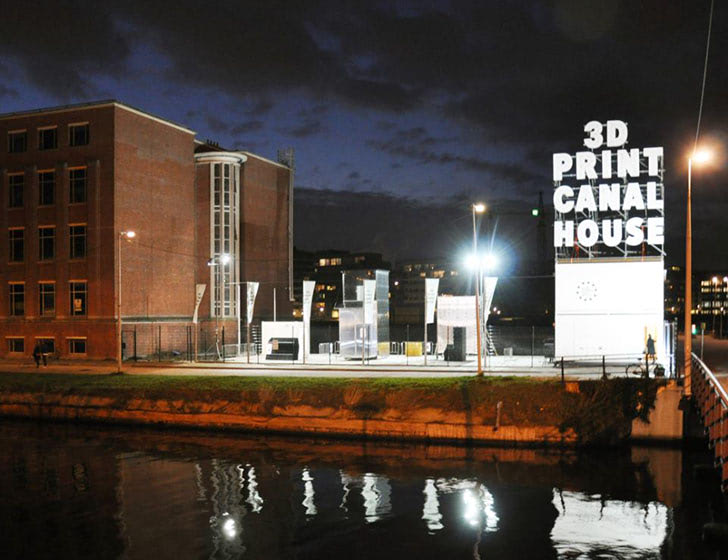

Dutch architects at Dus, together with Ultimaker company, developed a giant version of the small desktop 3D printers. They created the first 3D Print Canal House exhibition, research- and building site for 3D Printing Architecture, in the heart of Amsterdam.

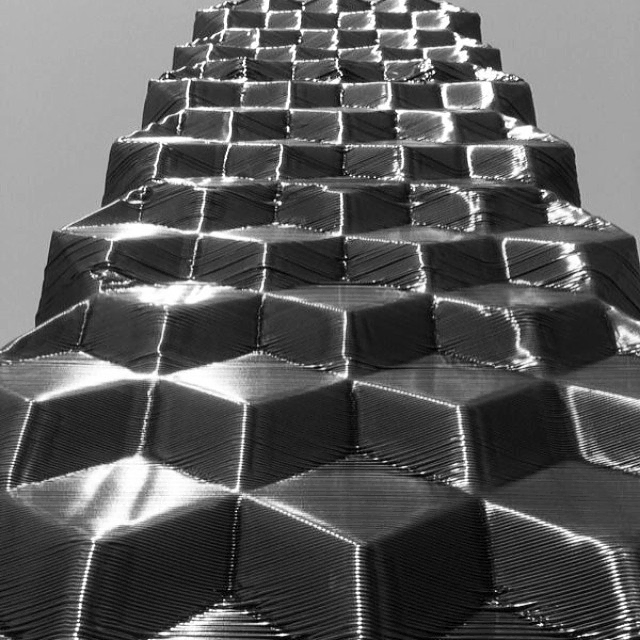

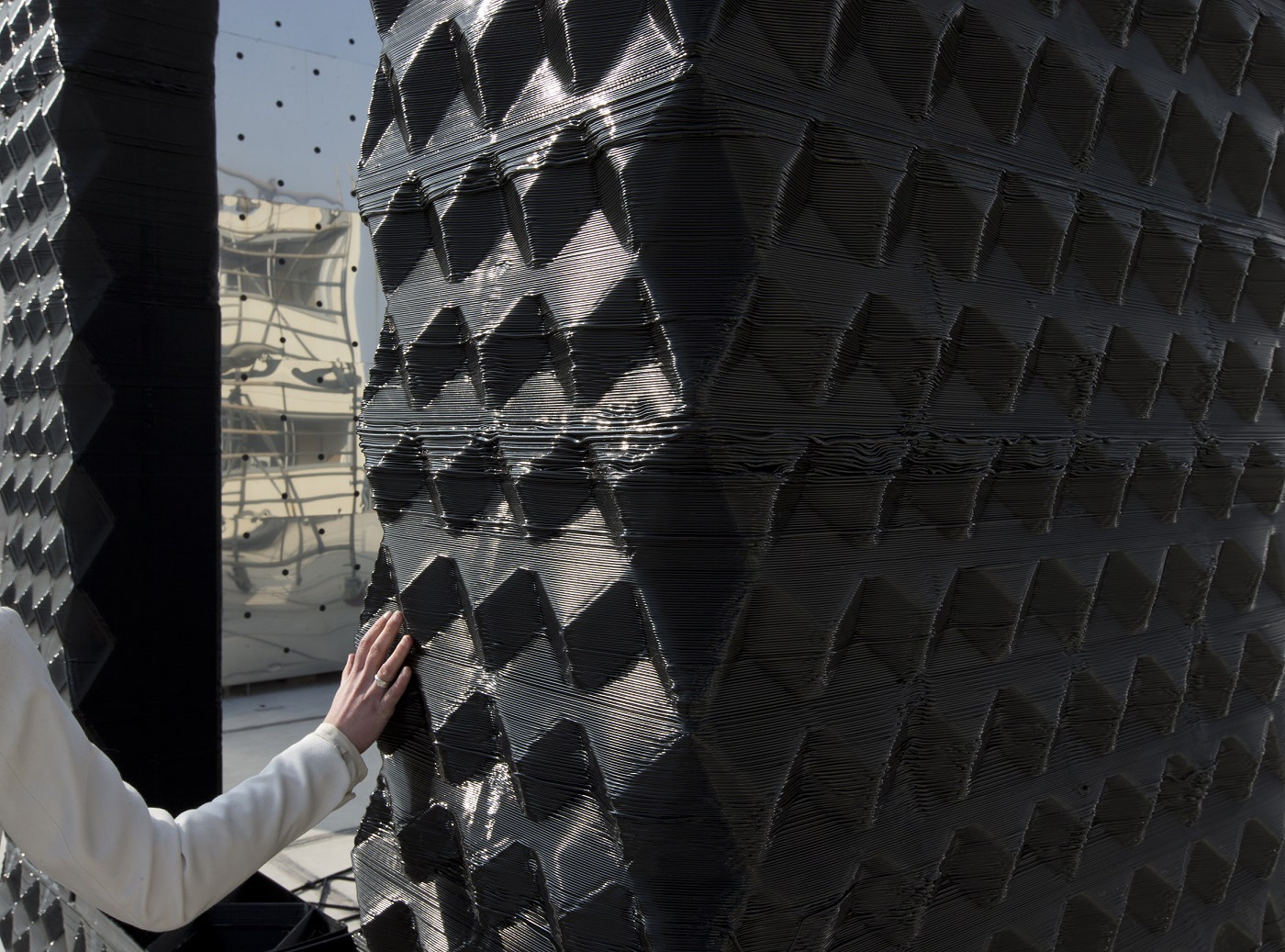

“With 3D-printing, there is zero waste, reduced transportation costs, and everything can be melted down and recycled. This could revolutionise how we make our cities.” Using a bio-plastic mix, the first sample is built with honeycomb structure and reinforced with concrete. “We will continue to test over the next three years, as the technology evolves,” Heinsman says. “With a second nozzle, you could print multiple materials simultaneously, with structure and insulation side by side.”

“This is only the beginning, but there could be endless possibilities, from printing functional solutions locally in slums and disaster areas, to high-end hotel rooms that are individually customised and printed in marble dust.”

The 3D Print Canal House is the first house being printed, however there are a number of other initiatives.

The University of Southern California, using Contour Crafting fabrication process, have been developing a computer-controlled gantry to print structures in quick-setting concrete.

Janjaap Ruijssenaars from Universe Architecture projects to print a Moebius strip house, with the Italian-made D-Shape printer, using sand mixed to create a form of synthetic sandstone.

Since 3D print is revolutionising the construction industry, suddenly the traditional way of building houses seems so old fashion!

Source: The Guardian

Comments (0)

Share your thoughts and join the technology debate!

No comments yet

Be the first to share your thoughts!